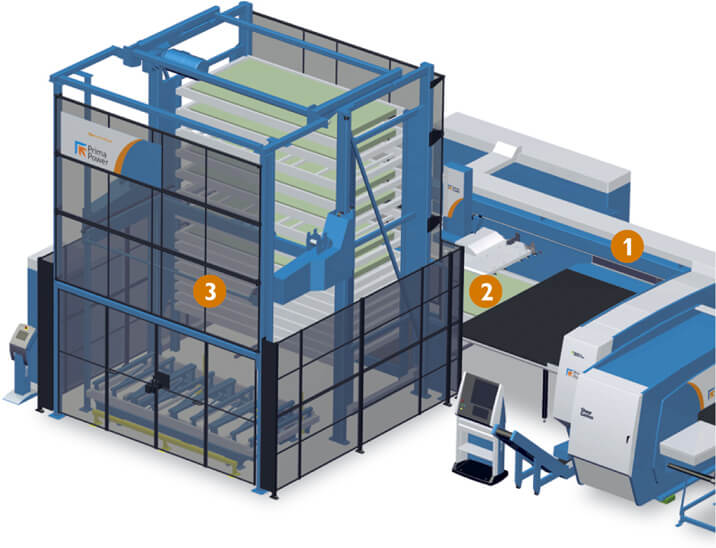

Dây chuyền cắt đột liên hợp LPEF

| Features | LPe6f / LPe8f | |

| Punching force | 200 kN / optional 300 kN | |

| Punch stroke | Electrical servo motor | |

| Ram stroke length in punching | Automatic intelligent optimization (NC-axis) | |

| Stroke depth adjustment | Programmable with 0.001 mm increment | |

| Stroke length adjustment | Programmable with 0.001mm increment | |

| Ram speed adjustment | Programmable | |

| Number of turret stations | 20 or 16 pieces all auto index stations | |

| Tools | Thick Turret | |

| Max punch diameter | 89 mm | |

| CNC Index Tool: Max. number of Index Tool stations | std. 2 pcs (max. 10 pcs) | |

| Max. punch diameter | 89 mm | |

| Max. tool rotation | 166 r/min | |

| Index upward forming system (option): Force | 200 kN | |

| Die height in forming | Programmable with 0,001 mm increment (max. 12 mm) | |

| Forming speed (2) (25 mm form-to-form distance) | 80 – 150 1/min | |

| Max material thickness: Mild Steel Stainless steel Aluminium |

Punching 8.0 mm 8.0 mm 8.0 mm |

Laser cutting, 2 / 3 / 4 kW fiber 8.0 / 8.0 / 8.0 mm 4.0 / 6.0 / 8.0 mm 4.0 / 6.0 / 8.0 mm |

| Min. material thickness | 0.5 mm | |

| Max. sheet weight (1) | 200 kg | |

| Clamps | pneumatic, 3 pcs (optional 4rd clamp) | |

| Max. sheet size (X x Y) , max. LPe6 | 3,074 mm x 1,565 mm , | |

| Max. sheet size (X x Y) , max. LPe8 | 4,300 mm x 1,565 mm | |

| Combined working area LPe6f/LPe8f (punch / laser) | 2,500 mm x 1,565 mm without repositioning | |

| X-traverse | 3,144 mm (X-42…X2,542) | |

| Y-traverse | 1,615 mm (Y-25…Y1,535) | |

| Max. axis speed (X-axis) | 120 m/min | |

| Max. axis speed (Y-axis) | 90 m/min | |

| Max traversing speed | 150 m/min | |

| Max. hit speed: (2) Nibbling (1 mm) | 1000 1/min | |

| Marking speed | 2,800 1/min | |

| Punching accuracy according to LKP-7300: (3) Laser accuracy according to LKP-7600: (4) Hole location deviation (X/Y axes), max. Hole-to-hole distance deviation (X/Y axes), max. Angular deviation (CNC Index Tool), max. |

0.1 mm ± 0.05 mm ± 0.1 |

|

| Positioning accuracy according to VDI/DGQ 3441: (5) Positional deviation Pa (X/Y axes) Positional scatter Ps (X/Y axes) |

0.08 mm (± 0.04 mm) 0.04 mm (± 0.02 mm) |

|

| Turret rotation | 30 r/min | |

| Tool change time (6) | 1 … 3 sec | |

| Work chute, max. part size (7): (X x Y) Punching Laser cutting |

chute 1. 500 mm x 500 mm chute 1. 300 mm x 400 mm; chute 2. 800 mm x 800 mm |

|

| CNC control | PC based CNC 19” Touch screen, Windows™ – based user interface |

|

| Total weight | 15,000 kg | |

| Electrical connection (E1) Average power consumption (8) Requirements for connection power (9) Front fuse |

9 kW 35 kVA 3 x 50 A (with voltage 3 x 400 V) |

|

| Compressed air connection (P1) Compressed air pressure, min. Compressed air pressure, max. Max. air consumption Average air consumption (10) |

6.5 bar 12 bar 8 Nl/s 5.5 Nl/s |

|

| Central lubrication tank | 2,000 cm³ | |

| LASER SOURCE | ||

| Type | Fiber laser IPG YLS-2000 / 3000 / 4000 | |

| Size | 790 x 815 x 557.5 mm | |

| Weight | approx. 160 kg | |

| Excitation | Diode lasers | |

| Beam quality | 2,5 mm x mrad | |

| Beam wave length | 1.07 – 1.08 m | |

| Guaranteed beam output power max. | 2, 3 and 4 kW | |

| Beam power range | 200 – 2,100 W | |

| Beam power stability | ± 2 % | |

| Polarisation | Random | |

| Beam pulse frequency | 0 Hz (CW) or 1 to 5,000 Hz | |

| Pulse frequency width | 250 sec to CW | |

| Output Fiber Core Diameter | 50 µm | |

| Electrical connection (E2) Average power consumption (8) Requirements for connection power (9) Front fuse |

2 kW 23 kVA 3 x 32 A (with voltage 3x400V) |

|

| CUTTING HEAD | ||

| Type | Auto-focus cutting head with quick change lens cassette | |

| Focal length | 5” and 7.5” | |

| Focal length adjustment | Programmable | |

| Distance to material sensing | Programmable, capacitive (non-contacting) | |

| Adjustment of cutting gas pressure | via CNC control or manually | |

| Cutting gas pressure, max. (11) | 25 bar | |

| Cutting gas connection | 2 points, three points optional High pressure: 1 x / 2 x optional Low pressure: 1 x |

|

| Lens diameter | 1.5” | |

| CHILLER | ||

| Type, 2 kW / 3 and 4 kW | 2 kW: Hyfra Pedia CWK 70 S (50Hz) / 3 and 4 kW: Hyfra Pedia CWK 90 S (50Hz) | |

| Cooling capacity, 2 kW / 3 and 4 kW | 8 kW / 10 kW | |

| Cooling water temperature: primary circuit | 20° C ±1° | |

| secondary circuit | No secondary circuit! | |

| Chiller unit weight (w/o water), 2 kW / 3 and 4 kW | approx 130 kg / 180 kg | |

| Volume of chiller water tank | 26 litres | |

| Dimensions | 720 mm x 720 mm x 755 mm ( l x w x h ) | |

| Noise level | 76 dB (A) 1m distance (A-weighted equivalent continuous sound pressure level | |

| DUST COLLECTOR | ||

| Type | Herding DELTA 750-4/9 SB | |

| Size | 1,200 mm x 8,35 mm x 2,120 mm ( l x w x h ) | |

| Weight | 580 kg | |

| Air flow | 500 m³ | |

| Filters | 4 x DELTA 750/9 3K, clean gas side mounted | |

| Filter area | 7.3 m² | |

| Noise level CE (DIN 45635-3) 1m: | 74 dB (A) in 3m (A-weighted equivalent continuous sound pressure level | |

| Mean permeability (12) | 0.01% | |